Environmental

We believe that business growth must go hand-in-hand with environmental stewardship. We continuously adapt to evolving environmental laws and regulations, and we're proud to have achieved ISO 14001 environmental management system certification for 100% of our operations in Thailand, covering both our Bangna and Samrong factories. This commitment ensures our reliability and builds trust in our operations. As a result, we've had zero environmental incidents or fines from 2021 to 2024. Key performance highlights are summarized below:

We recognize that creating eco-friendly innovations is a key driver for sustainable production and consumption within the country. Driven by our commitment to offer sustainable choices and enhance societal well-being, in 2024 we expanded our TOA Greenovation concept. This approach simplifies painting work without compromising quality or environmental care. This led to the development of "TOA Shield Expert," a ready-to-use water-based paint. We've received excellent cooperation from property developers in testing its real-world performance. Additionally, we fostered a culture of innovation through the "TOA Super OKRs Challenge," engaging 136 employees from all departments and generating 29 new ideas.

TOA Shield Expert

TOA Super OKRs Challenge

Biodiversity loss is an escalating crisis, largely driven by human activities. In response to this critical issue, our company has implemented a comprehensive biodiversity management approach. This begins with the establishment of clear policies and the assessment of biodiversity impacts using tools such as ENCORE (Exploring Natural Capital Opportunities, Risks and Exposure) and IBAT (Integrated Biodiversity Assessment Tool), following a mitigation hierarchy approach and aiming to restore natural ecosystems in collaboration with stakeholders under the “TOA Love Us, Love the World” project. To date, this initiative has successfully restored and reforested an additional 1,740 rai, earning us a Plaque of Honor from the Royal Forest Department in 2024 as a “Supporter of the Royal Forest Department in the Area of Forest Resource Restoration and Development.”

“TOA Love Us, Love the World” project

Our company is committed to continuously improving our energy performance, adhering to the international ISO 50001 energy management standard. We've established a clear energy policy and appointed a dedicated team to drive efficient energy use toward our goals.

We achieve this through two main strategies: enhancing energy efficiency and promoting renewable energy generation technologies. In 2024, we successfully reduced electricity consumption by 2,088,138 kWh per year, which translates to a reduction of 926 tons of CO2 equivalent greenhouse gas emissions.

Solar Rooftop Installation

Our company prioritizes efficient resource use and social responsibility. To address risks and ensure operational continuity, we've implemented a comprehensive water management strategy. This includes establishing a dedicated water management team to regularly monitor our water consumption.

We're committed to improving our wastewater treatment systems to enable water reuse within our facilities. This goes hand-in-hand with maintaining our water supply systems and promoting water conservation. In 2024, we successfully reused 10,212.60 cubic meters of wastewater. Furthermore, our nanofiltration wastewater treatment ensures that the Chemical Oxygen Demand (COD) is 50% below the legal limit.

We prioritize sustainable waste and refuse management to safeguard our planet from the negative effects of improper disposal. Our long-term vision is Zero Waste to Landfill by 2030, a goal we're pursuing through a structured Waste Management Hierarchy. We empower our employees to adopt responsible waste reduction and management practices. For instance, we successfully recycled 544 old uniforms into 465 new ones, and repurpose display materials from Architect’67 for educational use.

Closed-Loop Recycled Clothes Project

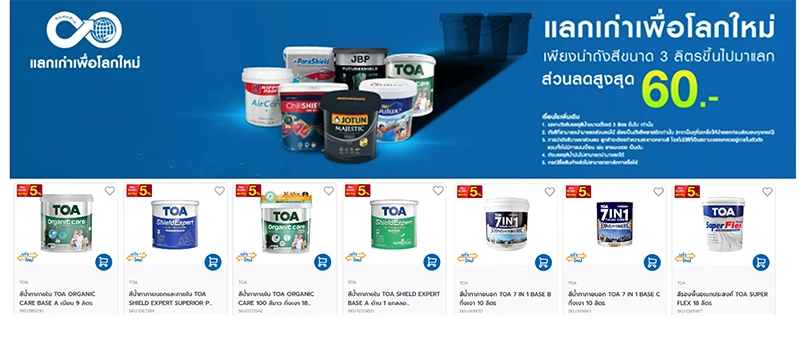

Beyond internal efforts, we recognize the importance of product life cycles and post-consumer material management in the construction industry. We're collaborating with partners on various initiatives. Our “Trade-in for a Better Life” project with HomePro and MegaHome allows customers to exchange old paint cans for discounts on new products. Additionally, through the "Eco-Friendly Gypsum Ceiling" project with Supalai Public Company Limited, we successfully reprocessed 13.26% of gypsum ceiling waste, reducing overall waste by over 10% and cutting greenhouse gas emissions by 2.50 kg CO2 equivalent per square meter.

“Trade-in for a Better Life” Project

Eco-Friendly Gypsum Ceiling

Eco-Friendly Gypsum Ceiling

Our company is committed to stringent air quality management to mitigate the impact of dust and air pollution generated by our production processes. We prioritize continuous air quality monitoring in both operational areas and at exhaust stacks. Furthermore, we implement technology to manage pollution at its source. This includes increasing the frequency of air filter replacement, altering ventilation directions, converting production to closed systems, and installing localized air filtration systems. These measures ensure that our air quality meets established standards. As a result, in 2024, there were no significant air quality complaints from surrounding communities, which aligns with our set goals.

Implementing a Closed-Loop Production System

Installing Air Filtration Systems for Each Area